Do You Really Need Optical Bonding? Here's When It Matters (and When It Doesn't)

Optical bonding improves display clarity and durability but when is it worth it? We break it down.

Optical bonding is one of those terms that sounds impressive and it is. But not every display project needs it.

Here’s how to know if your product should include optical bonding or if it’s an upgrade you can skip.

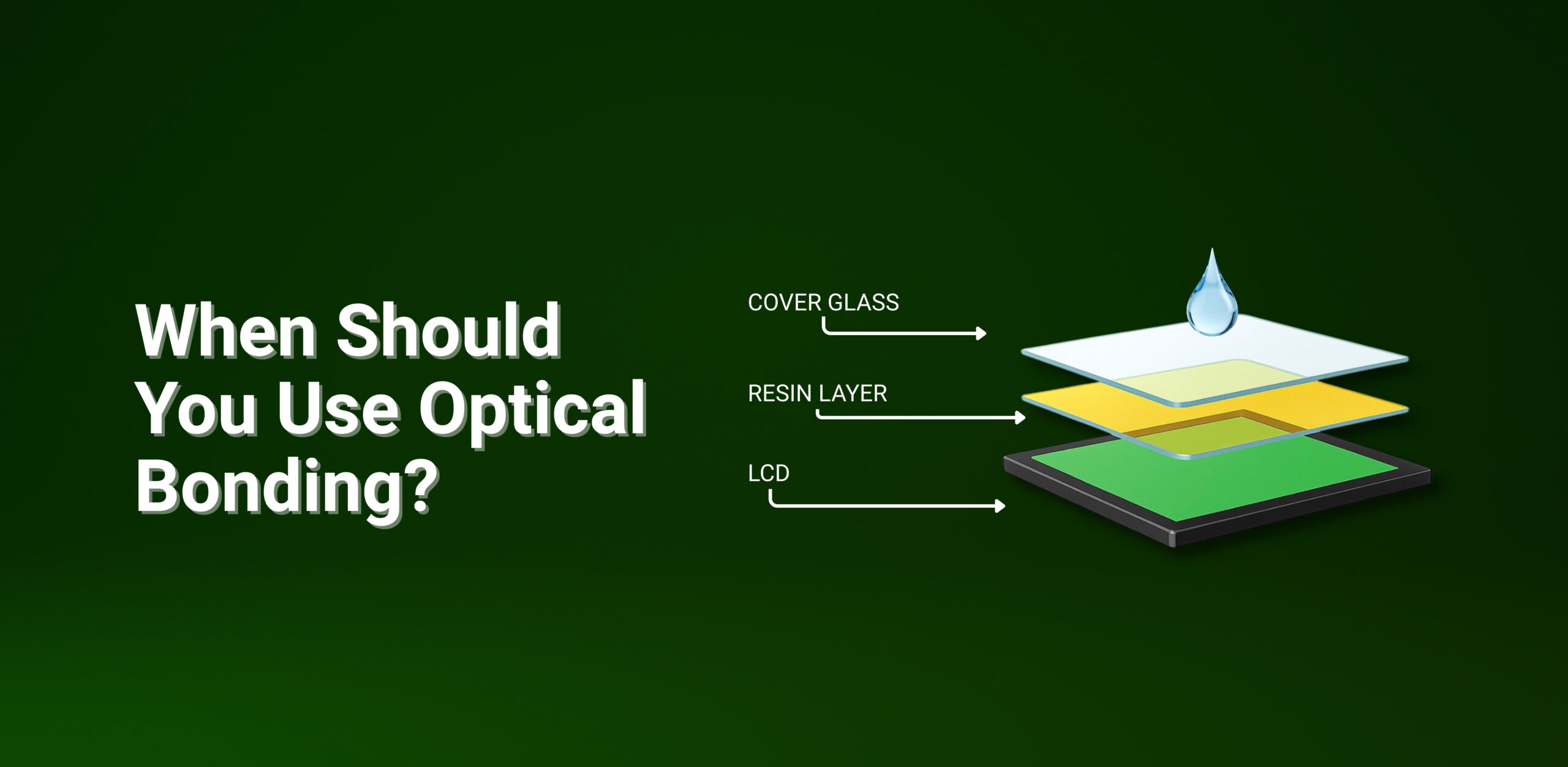

First, What Is Optical Bonding?

In a standard LCD, there’s usually an air gap between the screen and the cover lens. Optical bonding fills that gap with a transparent adhesive, creating a single optical layer.

The result? Better visibility, durability, and no fogging.

When You DO Need Optical Bonding

Outdoor Use

Bonding reduces internal reflections = better sunlight readability

Rugged/Industrial Use

Adds shock resistance and improves touchscreen durability

Marine / Humid Environments

Prevents fogging and moisture inside the panel

Touch Accuracy

Improves precision, especially in touch interfaces using gloves or styluses

When You DON’T Need It

- Indoor products without glare

- Enclosed devices with low exposure

- Projects with strict budgets

- Simple displays used only for readout (no interaction)

Can You Add It Later?

Yes, but it’s best to spec it early in your project.

We offer optical bonding as a factory-level or local service, depending on size and quantity.

Talk to us if you’re unsure. We’ll help you decide if bonding fits your environment and budget.