What Is Optical Bonding in LCDs and Why Does It Matter?

Optical bonding improves LCD durability, visibility, and touchscreen performance especially in rugged or outdoor environments. Learn how it works, why it matters, and how 4D LCD can help you integrate it into your next display project.

Let’s Talk Optical Bonding: A Game-Changer for LCD Performance

If you’ve ever used a device outdoors and struggled to see the screen or seen moisture fog up under the glass you’ve experienced firsthand what happens when an LCD isn’t built for real-world conditions. That’s where optical bonding comes in.

But what exactly is it?

What Is Optical Bonding?

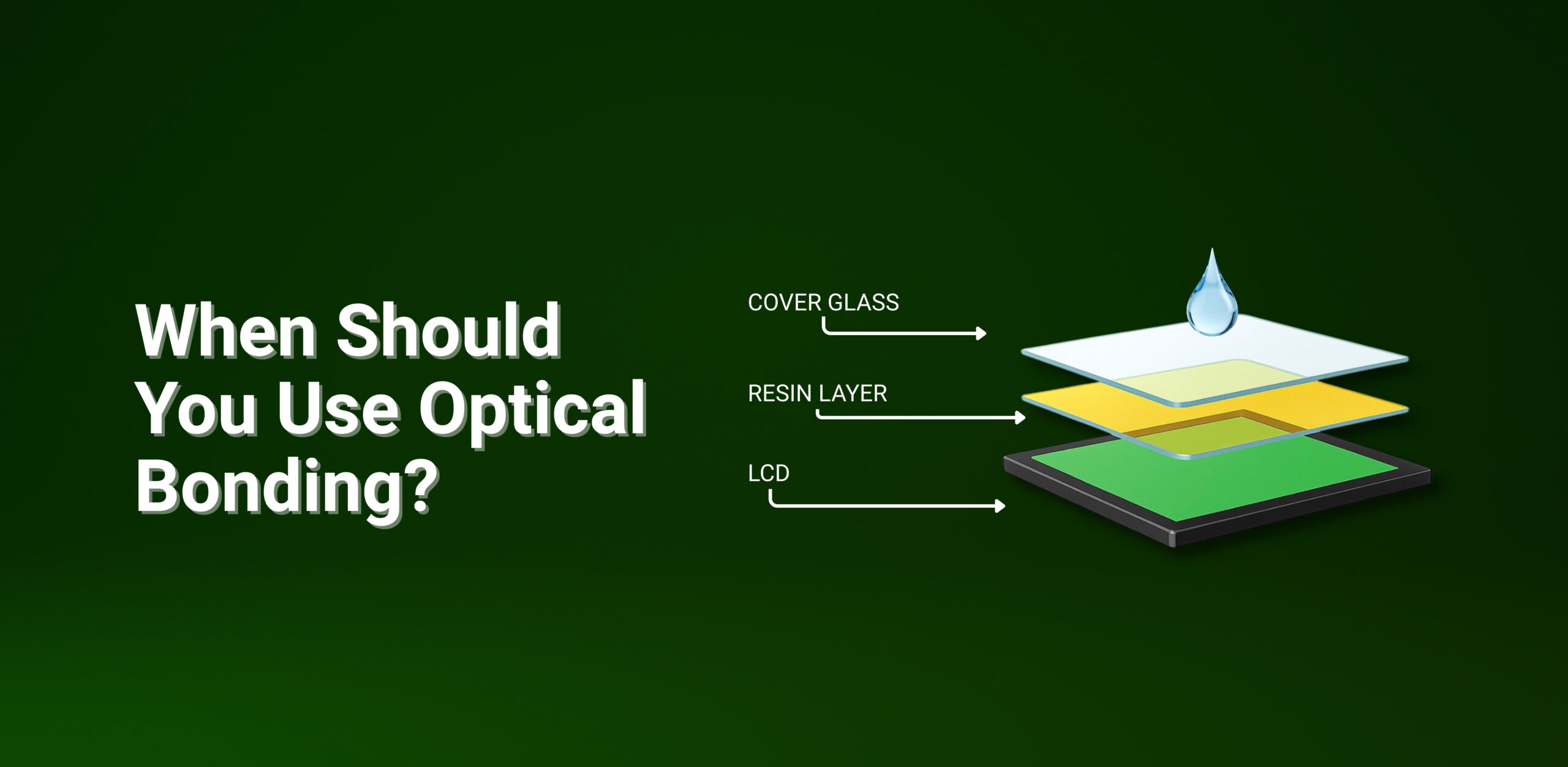

In a typical LCD, there’s a thin layer of air between the display panel and the cover glass. Optical bonding eliminates that gap by injecting a transparent adhesive (usually silicone or resin) between the two layers, creating a single, solid unit.

This simple process has a big impact on performance especially in rugged, industrial, or outdoor applications.

Benefits of Optical Bonding

1. Improved Sunlight Readability

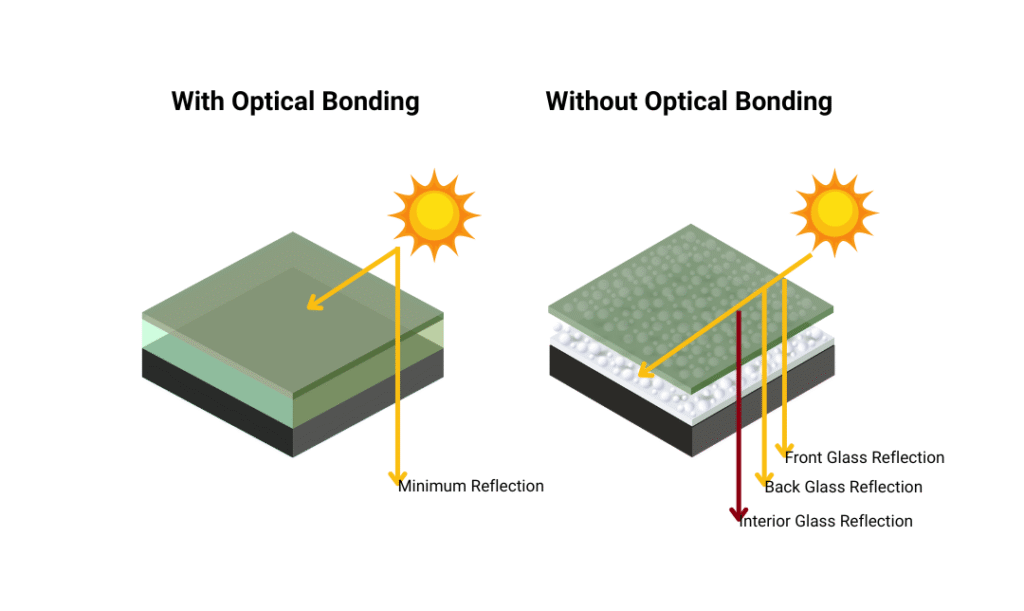

Removing the air gap reduces internal reflections and boosts contrast, making the screen easier to read in direct sunlight essential for outdoor devices, public kiosks, and field equipment.

2. Stronger, More Durable Displays

Bonded screens are more resistant to impact, vibration, and pressure. That makes them ideal for tough environments like mining, construction, logistics, or military applications.

3. No Fogging or Moisture Traps

The adhesive layer seals the display, preventing dust, dirt, and moisture from getting between the layers solving one of the most common failures in standard LCD assemblies.

4. Better Touch Accuracy

With the layers bonded together, the screen feels more responsive, stable, and precise especially useful in glove-friendly or multi-touch interfaces.

Where It’s Used

You’ll find optically bonded displays in industries like:

- Medical devices (requiring high hygiene standards and durability)

- Agricultural tech (operated in sun, rain, and dust)

- Transportation (dashboards, ticketing machines)

- Retail kiosks (for outdoor or high-traffic locations)

Why Choose 4D LCD for Optical Bonding?

-

At 4D LCD, we offer custom optical bonding services with full control over adhesive type, bonding thickness, display size, and environmental sealing. Whether you need a compact 2.4” bonded screen or a 15.6” outdoor panel, we’ll customise it for your product’s specific environment.

Don’t let glare, dust, or moisture hold your display back.

Get in touch with our team to learn how optical bonding can enhance your next LCD project functionally and visually.